Production

traditional methods at the service of passion

At the Brasserie Dupont, respect for tradition and unique savoir-faire are reflected in three iconic production methods. From heating on an open fire to the square flat-bottomed vats, via the horizontal second fermentation in the bottle, each stage contributes to the authenticity and character of our beers. Find out more about the techniques that have shaped our brewery’s identity.

Heating on an open fire

We heat our copper vats in direct contact with a flame. This traditional open-fire heating method gently caramelises the sugar.

Square flat-bottomed vats

These flat-bottomed vats are a rare sight in modern breweries. They play a key role in the complexity and richness of our beers and are the signature of our wide range. We have continued to use them at the Brasserie Dupont for more than 100 years, despite the space that they take up and the meticulous hand-cleaning that they require, inside and out. Their contribution to our savoir-faire make them indispensable.

Horizontal second fermentation

This is the traditional production method and our brewery’s signature! The beer is kept in horizontal bottles in a warm room for 4 to 6 weeks. This process produces our beers with no residual sugar. The flavour of the beer is honed and it becomes more complex.

The different stages of the brewing process

Mashing and filtering

Mashing involves mixing and heating the malt with water from our well. Over time, the starch turns into sugar. Next the wort (a sweet juice) is separated from the spent grain in the lauter tun. The spent grain is distributed to neighbouring farms and used to feed animals, while the wort goes on to be boiled...

Boiling

The wort is heated with hops, which gives each of our beers its unique bitterness and typical aromas. Our blend is heated over an open fire in our copper vats that date back to 1920.

Fermentation and maturing

Time to move on to the flat-bottomed vats: this is where the yeast is added, which turns the sugar into alcohol and CO2.

The beer is then aged in the conditioning room for 2 weeks, then clarified by centrifugation and sent to a bright beer tank.

In this tank, before bottling, a new yeast culture is also added.

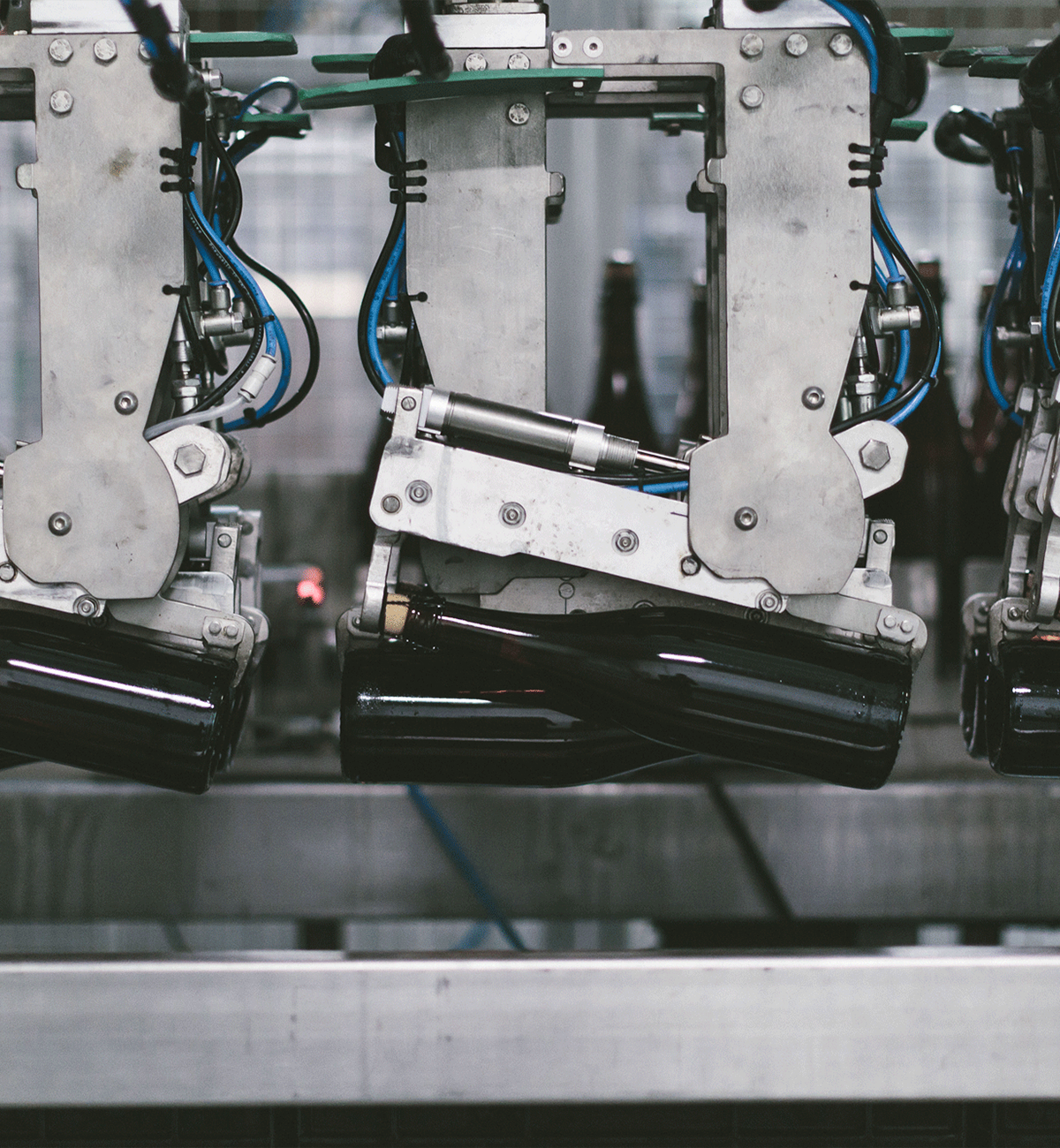

Bottling

In the bottles, the yeast turns the sugar into alcohol and CO2. This is what creates our beers’ bubbles and slight cloudiness!

Refermentation

Each bottle is kept in a warm room (23°c) for 4 to 6 weeks.

Once you’ve got your hands on the beer, you can keep it for many months, or even years, in your cellar. The flavours will only get more complex!